Chinese Cargo Ship Hits Bridge Collapsing Roadway and Killing Five People

Chinese authorities are reporting that a small cargo ship traveling on the Hingqili near the industrial southern city of Guangzhou hit a bridge crossing the waterway causing a section of the roadway to collapse. At least five vehicles plunged off the bridge with the latest reports saying five people have been killed, two are being treated in the hospital, and a search of the river was continuing.

The unidentified vessel was reported to be traveling in the Pearl River delta between Foshan and Guangzhou when the side of the vessel struck one support pillar of the bridge. According to the maritime authorities, the vessel twisted with the bow then coming in contact with a second support pillar. The roadway section between the two supports collapsed.

They believe that three small trucks, a minibus, and a motorcycle all plunged off the bridge. The small bus, one of the vehicles, and the motorcycle plunged into the open hopper barge. The other two vehicles fell into the river.

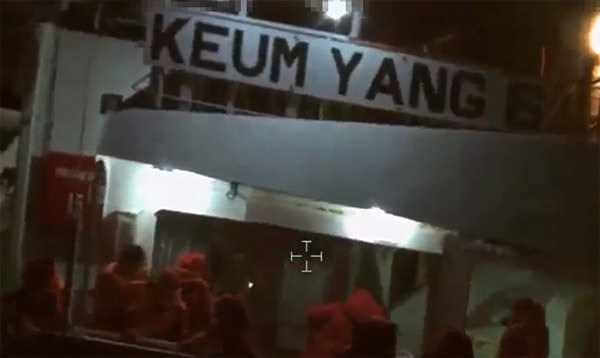

Authorities are saying the accident happened at 5:30 a.m. local time which may have helped to limit the number of causalities. The small bus was reported to only have a driver aboard and the wreckage can be seen in pictures of the cargo ship as it was being taken away.

The authorities in a news conference after the accident blamed the accident on “improper operation” of the cargo vessel. They said the owner of the ship had been detained. One crewmember aboard the vessel was reported to have suffered minor injuries.

Chinese TV reported that six scuba divers were seen scouring the river. Multiple salvage ships were also in the area.

The two-lane Lixinsha Bridge connected a rural island area to the industrial city. Officials said at least 8,000 people, mostly farmers would be isolated on the island without the roadway. They were starting a temporary ferry service while an investigation was also underway into the cause of the accident.

WSC、従来燃料にフィー課徴を。MEPCに提案、新燃料と価格差埋める

WSC、従来燃料にフィー課徴を。MEPCに提案、新燃料と価格差埋める